Introduction:

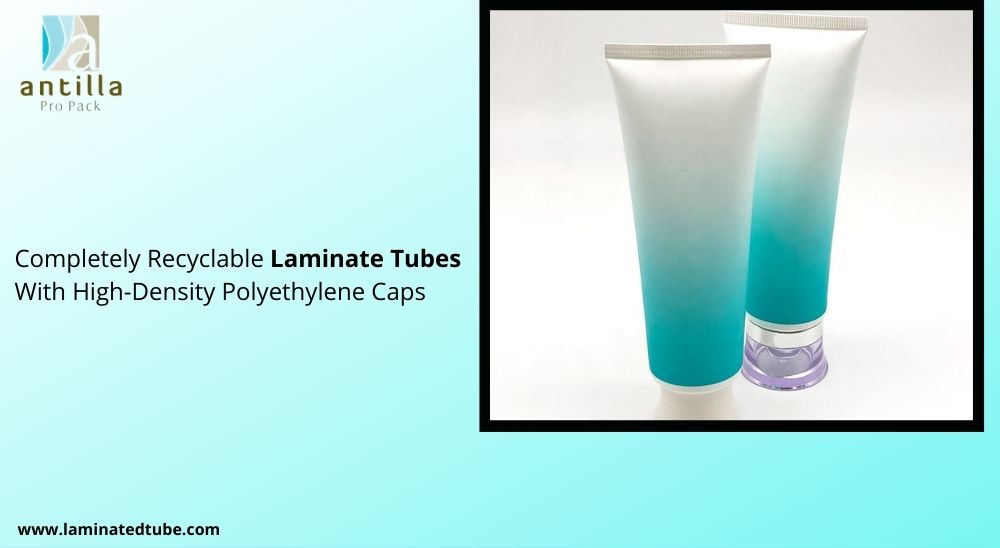

The principal completely recyclable polyethylene-based cylinders with high-thickness polyethylene flip-top covers are created in today’s era. Predictable with the lami tubes manufacturer the cylinders are a forward leap inside the overall push for bundling maintainability. The mono-material cylinder and cap mix conquer a longstanding usefulness obstacle for pivoted covers.

Uses of lami tubes:

The new completely recyclable lami tubes manufacturer include body, shoulder, and covers made utilizing a solitary material family. The mono-material tubes and cap, which is also being offered in screw-top organizations, are frequently utilized for well-being, food, and pharma bundling applications.

Well-being, food, and drug brands would now be able to guarantee their undeniable supportability. Likewise, they will help cognizant clients that the bundling during which their items are housed has the most minimal conceivable natural effect as we push toward an absolutely roundabout bundling economy.

Mono-material PE:

The organization features that mono-material plastic bundling is extremely more ideal in existing reusing streams than mixed plastics. As its similar effortlessness is considered completely recyclable in mechanical reusing plants and along these lines, it is critical to consider advancing toward a round bundling scene.

The business says that the new tubes are completely recyclable with the body, shoulder, and covers made out of one material family. The corporate says the tubes are ideal for pharma bundling applications, among others, accessible in screw-top arrangements.

Recyclable polyethylene tubes:

Cylinders are a half breed bundling with a flexible (body) and an unbending part (shoulder and cap), which brings about cylinders will be arranged and reused in discrete PE measures. As recyclers favour HDPE material, low-thickness polyethylene LDPE content must be limited.

PET and HDPE are the two generally regularly reused plastics and generally acknowledged by material recuperation offices that sort recyclables. HDPE recently had been thought too unbending even to consider forming a productive squeezable cylinder. In any case, the lami tube manufacturer created various evaluations and thicknesses of HDPE cover to make tubes that will be reused.

Cylindrical commercial tubes:

A central point of interest for a couple of customer item bundling is that the size includes mechanical reusing, with more modest items falling through sortation hardware at material recuperation communities and winding up inside the rubbish. Testing at MRFs shows that the organization’s normal toothpaste cylinders can endure MRFs and into the HDPE stream.

Future of tubes:

Various assembling organizations produce All-plastic cover tubes for oral consideration, additionally as care and pharma brands. They also offer a lower ecological effect than standard aluminium-based structures. The boundary web guarantees ideal equation security for all applications for different makers. The mechanical properties of its solid structure and coming-up-soon PE flip-top and screw covers could even withstand the expulsion of optional bundling.

Conclusion:

Accomplished along with a long-term producer, lami tube manufacturer produces the new HDPE flip-top covers defeat the last obstacle to recyclable cylinder bundling to be specific. The ability to make practical terminations from an identical material is overwhelmed on the grounds of the cylinder body and shoulder.